Describe the Advantages of Using Precast Concrete Floor Components

Following are the advantages of precast concrete. The transport and storage of various components of concrete for cast-in-situ work are eliminated when pre-cast members are adopted.

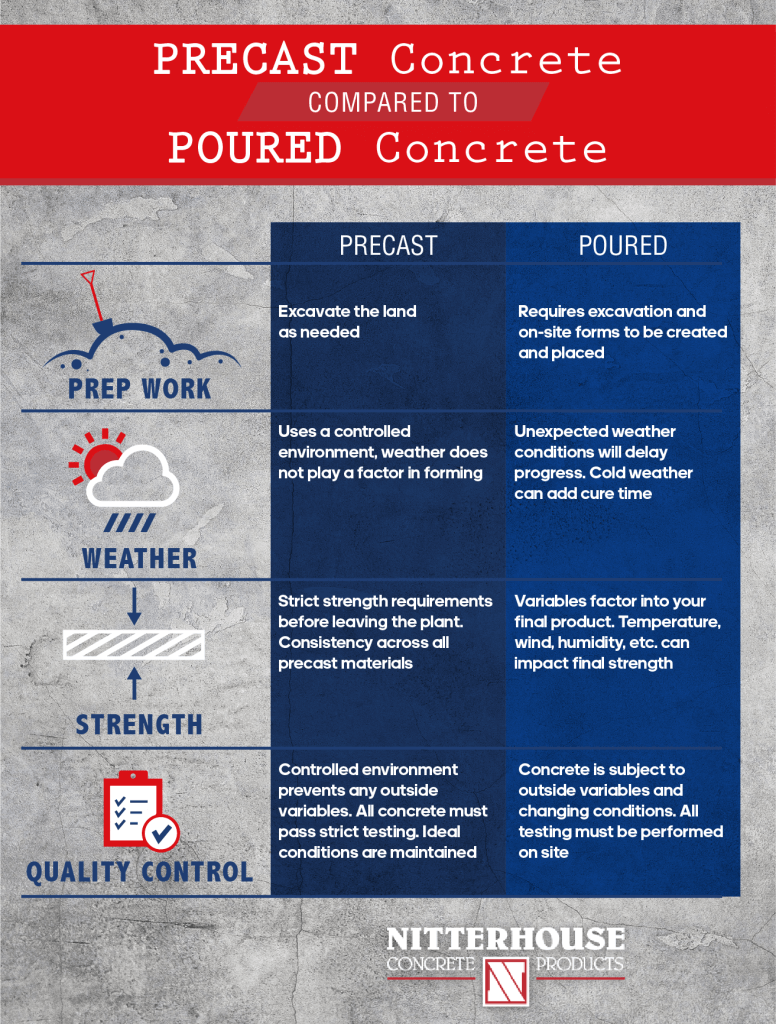

Precast Concrete Vs Site Cast Concrete Nitterhouse

That in turn reduces insurance rates.

. The labour required in the manufacturing process of the precast units can easily. Quality of produced concrete is superior due to better control on the concrete production in the factory. It is not necessary to provide joints in the precast construction.

The precast concrete foundation is constructed in a controlled environment and hence it follows strict quality control. Batching of concrete components. The precast concrete foundation units are stronger and lighter when compared to other competing materials.

Precast concrete is poured into molds and then cured in a controlled climate. Quality Durability Dimensional accuracy Tight tolerances Speed of constructionReduction of. There is greater control over material quality and workmanship in a precast plant compared to a construction site.

The adoption of concrete floor speeds the completion of the ground floor. Precast concrete is weather-and-fireproof and resistant to mildew and rust. As better quality control can be exercised in the factory or yard site concrete of superior quality can be produced.

Required labour manpower can be trained easily. Laying of concrete in required formwork with or without reinforcement as per design. Benefits of Precast Concrete Saving time.

The important advantages of precast concrete foundation are. Precast Concrete construction saves time the risk of project delay is also less. Precast members have very high erection speed.

Once cured the wall panels are rigorously tested to ensure quality and strength. This is used for water retaining floors as well as stores. There are many benefits associated with the use of precast concrete componentsOf course these require proper design use of the correct materials and manufacturing processes with skilled and knowledgeable personnel.

The materials used in precast concrete production are easily obtainable. When pre-cast structures are to be installed it is evident that the amount of scaffolding and formwork is considerably reduced. Given below a wide array of benefits for utilizing precast concrete construction.

14 Advantages of Precast Concrete Construction 141 Reduced Construction Time and Cost. Transporting the inserted member on site. Concrete floor is nonabsorbent and hence offers sufficient resistance to dampness.

Advantages and Disadvantages Precast Cement Concrete Blocks Construction are. Precast products are manufactured in a casting area where critical. Desired finish and shape can be given with high accuracy.

Advantages of Precast Concrete Process Structural efficiency Flexibility in use Optimum use of materials Speed of construction Quality consciousness Adaptability. Advantages Of Precast Concrete Construction. Advantages of Precast Concrete Saves Construction Time.

Precast concrete never needs an umbrella laughs in the face of floods and stands strong in fires. Precast concrete is produced in a factory with advanced construction techniques. The key factors which regulate the quality of construction such as curing temperature mix design.

142 High quality and aesthetical value of products. Then those panels are shipped out to the construction site ready for installation. Advantages of Precast Concrete.

Because the concrete components were put together in a factory using the same moulds over and over it is. Since precast is manufactured in a controlled casting environment it is easier to control the mix placement and curing. Advantages of Precast Concrete 1.

Because the parts being used come already created no time is wasted forming framing pouring or curing. Precast flooring systems have the added advantage of reducing the amount of labour required on site. Here are eight other advantages.

Other Inherent Benefits Architectural precast concrete is non-combustible with inherent fire-resistant capability creating a safe envelope that helps protect personnel equipment and the building itself. There is no necessity of provision of joints in the precast construction. Precast concrete advantages and disadvantages.

It also survives many more wintry freeze-thaw cycles than lesser building materials which expand and contract and eventually wear down. Reduced Construction Time and Cost With precast concrete construction it is possible to save significant time as well as minimize the risk associated with loiter of project and prospective financial losses. Employing a precast concrete foundation construction techniques helps to minimize the.

The concrete of superior quality is produced as it is possible to have better technical control on the production of concrete in factory. With all the advantages of using precast concrete its no wonder the civilized world can depend on the inherent quality value and permanence of precast concrete. Most of the advantages they cite are really advantages of concrete in general rather than specific to precast but when compared to site-cast concrete precast does have lots of advantages.

It also eliminates the need and cost of additional fireproofing measures except on structural-steel frames. Using a precast concrete system offers many potential advantages over onsite casting. When identical members are cast it is advantageous for the same formwork to be used.

Precast concrete construction will save valuable time and helps to reduce the. They have good quality control. Precast concrete has several advantages over cast-in-situ concrete.

Precast concrete production can be performed on ground level which helps with safety throughout a project.

Precast Concrete Types Advantages Disadvantages

No comments for "Describe the Advantages of Using Precast Concrete Floor Components"

Post a Comment